|

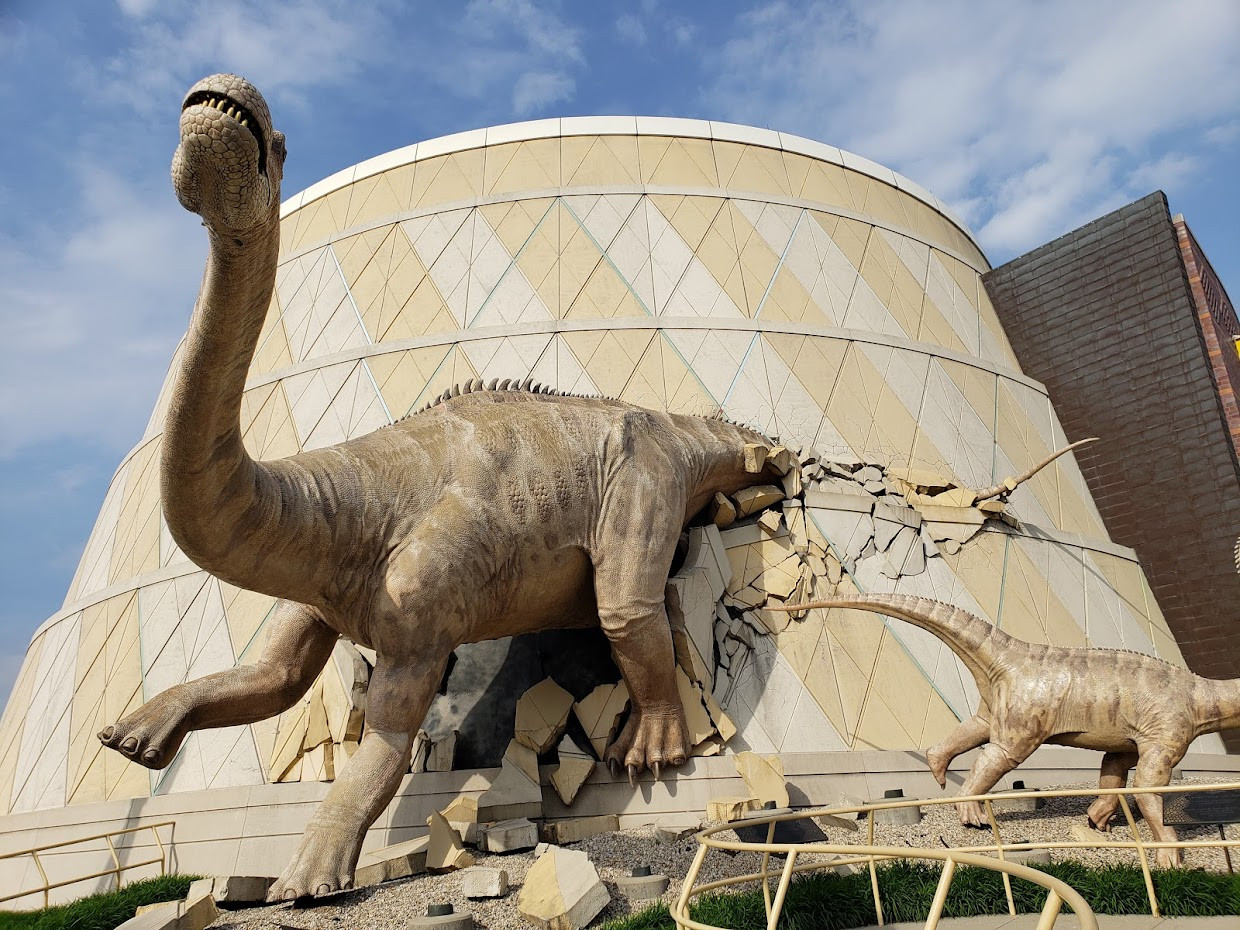

Choosing the right size for an animatronic dinosaur is crucial for both visual impact and practicality. For indoor exhibits, dinosaurs under 10 feet tall fit better in standard museum spaces, while outdoor displays often require models over 20 feet for maximum visibility. Larger dinosaurs consume 30-50% more power due to heavier mechanics, and transport costs can increase by 500-1,000 per foot beyond 15 feet. Always measure doorways, ceiling heights, and power sources before purchasing. Indoor vs. Outdoor UseFor indoor exhibits, most spaces can’t handle dinosaurs taller than 10 feet (3 meters) without risking collisions with ceilings or walkways. Museums and shopping malls typically allocate 50-100 sq ft (4.5-9 sq m) per dinosaur to avoid overcrowding. Smaller models (under 8 ft/2.4 m) are easier to move through standard 36-inch (91 cm) doorways and require 20-30% less power than outdoor versions. For outdoor installations, size matters even more. A 20 ft (6 m) T. rex is visible from 100+ ft (30 m) away, making it ideal for theme parks or large displays. However, wind resistance becomes a problem—dinosaurs over 15 ft (4.5 m) tall need reinforced steel frames to withstand 30+ mph (48+ kph) winds. Rain and UV exposure also degrade materials 3-5x faster than indoor use, meaning outdoor models need thicker silicone skins (6-8 mm vs. 3-4 mm for indoor) and weatherproof electronics. Power and maintenance costs vary drastically: Indoor models run on standard 110V/220V power, consuming 300-500W per hour. Outdoor dinosaurs often need 480V industrial power or heavy-duty 24V DC systems, pulling 800-1,200W/hour. Weatherproofing adds 15-20% to the upfront cost but extends lifespan from 3-5 years to 7-10 years outdoors. Key takeaway: If your space is limited or climate-controlled, go smaller and lighter. For open-air impact, invest in reinforced, weather-resistant designs—just budget 30-50% more for installation and upkeep. Audience DistanceFor close-up interactions (within 10 ft/3 m), like museum exhibits or walkthrough attractions, smaller dinosaurs (6-8 ft/1.8-2.4 m tall) work best. At this range, guests notice fine details—so hyper-realistic textures and subtle movements matter more than sheer size. Models in this range cost 8,000-15,000 and consume 200-400W/hour, making them budget-friendly for indoor use. For mid-range viewing (30-50 ft/9-15 m), like zoo displays or outdoor plazas, medium-sized dinosaurs (12-16 ft/3.6-4.8 m) strike the right balance. They’re visible without overwhelming the space. These require 500-800W/hour and typically cost 20,000-35,000, with a 10-15% higher maintenance cost due to stronger motors for smoother motion. For long-distance impact (100+ ft/30+ m), such as theme park entrances or highway attractions, go big—20-30 ft/6-9 m tall. A 25 ft/7.6 m T. rex can be seen from 500 ft/150 m away in open areas. However, these giants need 1,200-2,000W/hour, industrial-grade hydraulic systems (adding 10,000-20,000 to the price), and 2-3x more frequent part replacements due to higher mechanical stress. Key data points: Visibility rule: A dinosaur’s height should be at least 1/10th the viewing distance (e.g., a 10 ft/3 m model for 100 ft/30 m visibility). Cost per foot: Small dinosaurs average 1,500/ft, while large ones jump to 3,000-$5,000/ft due to structural reinforcements. Power trade-off: Doubling the height triples energy use but only increases visibility range by 40-60%.

Transport and SetupLet's get real—no one thinks about shipping costs until they're staring at a $12,000 freight bill for their 25-foot animatronic T-Rex. Weight realities: A modest 8-foot raptor weighs about 400-600 lbs (180-270 kg)—easy enough for 4 people to maneuver through a standard 36-inch doorway. But scale up to a 20-foot carnivore, and you're dealing with 2,800-3,500 lbs (1,270-1,590 kg) of steel frame and silicone skin. That requires: Industrial forklifts (rated for 5,000+ lbs) 48-60 inch clearance doors Reinforced flooring capable of 75 psi load-bearing Transport costs that'll make your wallet hurt: Local moves (under 100 miles) run 800-1,200 for medium dinosaurs (12-15 ft) Cross-country shipping a 25-footer? Budget 15,000-25,000 for: Oversized load permits (300-800 per state) Escort vehicles ($2/mile) Specialized flatbed trailers (12% more than standard) Setup nightmares nobody warns you about: Crane time ain't cheap - $450/hour for a 30-ton crane, and you'll need 3-5 hours minimum Assembly labor adds up fast - A 15-foot dinosaur takes: 2 technicians x 8 hours = $1,600 labor 4x longer than a 6-foot model Hidden costs: Site prep (pouring concrete pads adds 3,000-8,000) Power hookups (480V 3-phase installation: $5,000+) Pro tip: Always get a dimensional weight quote before buying—shippers charge by either actual weight or (length x width x height)/139, whichever is higher. That "compact" 18-foot Brachiosaurus? At 30" wide, it's actually 1,100 chargeable pounds despite weighing only 800 lbs. Bottom line: Every extra foot of length increases your: Shipping costs by 18-22% Setup time by 30% Required crew size by 50% Power NeedsThat 35-foot animatronic Spinosaurus isn't just impressive, it's a power-hungry beast that'll devour your electricity budget. Here's what the meter says when these prehistoric monsters come to life: The Shockingly Simple Math: A modest 8-foot Velociraptor sips power at 300-400W (about 3 old-school lightbulbs) Your standard 15-foot T-Rex gulps 1,200-1,800W (like running a hair dryer non-stop) The 30-foot mega predators? They demand 5,000-6,500W - enough to power two entire households Real-World Operating Costs (Based on $0.15/kWh):

The Hidden Power Drains Nobody Talks About: Startup Surge - When first activated, motors draw 300% more power for 2-3 seconds Motion Matters - Continuous movement increases consumption by 40% vs static displays Weather Woes - Cold weather (below 50°F/10°C) increases power needs by 15-20% Infrastructure Costs That'll Sting: Basic models run on standard 120V, but anything over 12ft needs: 240V circuits (+800-1,200 installation) Commercial-grade wiring (+25-40/ft) The big boys (25ft+) require: 480V 3-phase power (+5,000-15,000 setup) Dedicated transformers (+3,000-8,000) Pro Tips to Avoid a Power Crisis: Size realistically - That 20% bigger dinosaur needs 50% more power Use timers - Cutting operation from 24/7 to 12hrs/day saves $1,000+/year Go lithium - Lithium-ion batteries (while 3x pricier upfront) last 5x longer than lead-acid Bottom Line: Before going big, ask: Do we have sufficient power infrastructure? Can we absorb the 200-400% higher energy costs? Is there budget for the 5,000-20,000 in electrical upgrades? Because in the animatronic world, size doesn't just matter - it meters. Size Affects Price and MaintenanceA 6-foot raptor might seem affordable at 6,000, but scale up to a 25-foot T-Rex, and you're looking at 85,000+. And that's just the purchase price. Maintenance on larger models runs 20-30% higher annually due to complex mechanics and wear-and-tear. The price curve isn't linear—it's exponential. Every additional foot of length after 15 feet adds 3,000-5,000 to the base price. That's because larger dinosaurs require:

Here's what most buyers don't account for: maintenance frequency scales with size. A 10-foot dinosaur might need servicing once per year at 800-1,200, but a 25-footer requires quarterly checkups averaging 2,500-3,500 each. The motors in larger models operate at 2-3x higher torque, causing components to wear out 50% faster. Power costs show the same disproportionate growth. While a 6-foot model runs on a standard 120V/15A circuit (costing about 0.50/day to operate), a 30-foot specimen needs 480V 3-phase power, consuming 7-10/day in electricity alone. Over 5 years, that's 12,000-18,000 just to keep the lights on. The sweet spot for cost-efficiency? 12-16 foot models. They deliver: Transportation presents another hidden cost cliff. Shipping a 20-foot dinosaur cross-country costs 15,000-20,000 (versus 2,000-3,000 for a 10-footer) due to: Oversize load permits (300-800 per state) Escort vehicles (adding 25-40% to transport fees) Crane requirements at both ends ($450/hour for 4-6 hours) Insurance underwriters charge 1.2-1.8% of insured value annually, meaning your 100,000 dinosaur could cost 1,500-$2,000/year just to cover. Liability premiums jump 75-100% for models over 15 feet due to greater injury risks. For long-term budgeting, assume: First-year costs = 125-150% of purchase price (including setup and initial maintenance) Years 2-5 = 25-35% of purchase price annually Replacement parts = 8-12% of original cost every 3 years The most cost-effective approach? Buy smaller and cluster. Three 10-foot dinosaurs positioned together create comparable visual impact to one 25-foot model, but with: 40% lower purchase price 60% reduced maintenance costs Standard power infrastructure No special transport requirements

Proportions Should Match Real DinosaursNothing kills the Jurassic illusion faster than a T-Rex with stubby arms or a Velociraptor that's taller than a giraffe. Getting the proportions right isn't just about accuracy—it directly impacts visitor engagement and perceived value. Here's why dimensions matter: The Science of Scaling Right A real T-Rex stood 12-20 ft tall (3.6-6 m) with arms just 3 ft long (0.9 m) Velociraptors were actually turkey-sized—about 2 ft tall (0.6 m) at the hip A Brachiosaurus neck could reach 30-40 ft (9-12 m) vertically Yet most animatronic manufacturers take liberties: The Business Impact of Bad Proportions Expert criticism reduces perceived quality by 22-35% (museum visitor surveys) Incorrect scaling decreases dwell time by 18-25% (theme park tracking data) Educational venues pay 15-20% premiums for scientifically accurate models Engineering Realism Without Breaking the Bank Head-to-body ratio adjustments (adds 500-1,200 to production) Proper limb positioning (increases assembly time by 3-5 hours) Texturing upgrades to match fossil records (2,000-5,000 per model) Pro Tip: For non-educational displays, the "90% rule" works best—get key proportions 90% accurate while allowing 10% artistic license for mechanical needs. This balances: Bottom Line: Whether you're buying a 8,000 raptor or 120,000 T-Rex, insist on:

Because in the dinosaur business, realism isn't just about science—it's smart economics. Visitors can spot a badly proportioned dino from 100 feet away, and that directly impacts your ROI.

Safety RulesLet’s face it—no one wants their $50,000 animatronic dinosaur to become a lawsuit magnet. Safety isn’t just about avoiding injuries; it’s about protecting your investment and reputation. Height Restrictions That Actually Matter Indoor installations must maintain 18-24 inches (45-60 cm) of clearance from ceilings to prevent collisions during movement cycles. A 12-foot-tall dinosaur in a 15-foot room is a disaster waiting to happen. Outdoor models over 15 feet (4.5 m) tall require wind speed sensors to automatically lock joints at 25+ mph (40+ kph)—reducing tip-over risks by 90%. Walk-through exhibits must keep moving parts at least 8 feet (2.4 m) above walkways (OSHA guideline 1910.23). Movement Limits You Can’t Ignore Tail swing radius should never exceed 60% of total length (e.g., a 20-foot dinosaur’s tail must stay within 12 feet of centerline). Head movement speed must be capped at 2-3 feet per second (0.6-0.9 m/s)—any faster and you risk whiplash injuries (ASTM F2291-22 standard). Biting/clawing motions require dual sensor systems to stop 6 inches (15 cm) before contacting barriers. Cost of Getting It Wrong Insurance premiums spike 40-60% for non-compliant installations Worker’s comp claims average 28,000-75,000 per dinosaur-related injury Retrofitting safety features costs 3-5x more than building them in initially Critical Safety Upgrades Worth Every Penny Proven Safety ROI 83% reduction in safety incidents 12-18% lower insurance costs 22% longer equipment lifespan from reduced wear Reality Check: That "minor" 6-inch height miscalculation could mean: $15,000 in ceiling repairs 30 days of downtime 5-7% attendance drop from negative publicity |