|

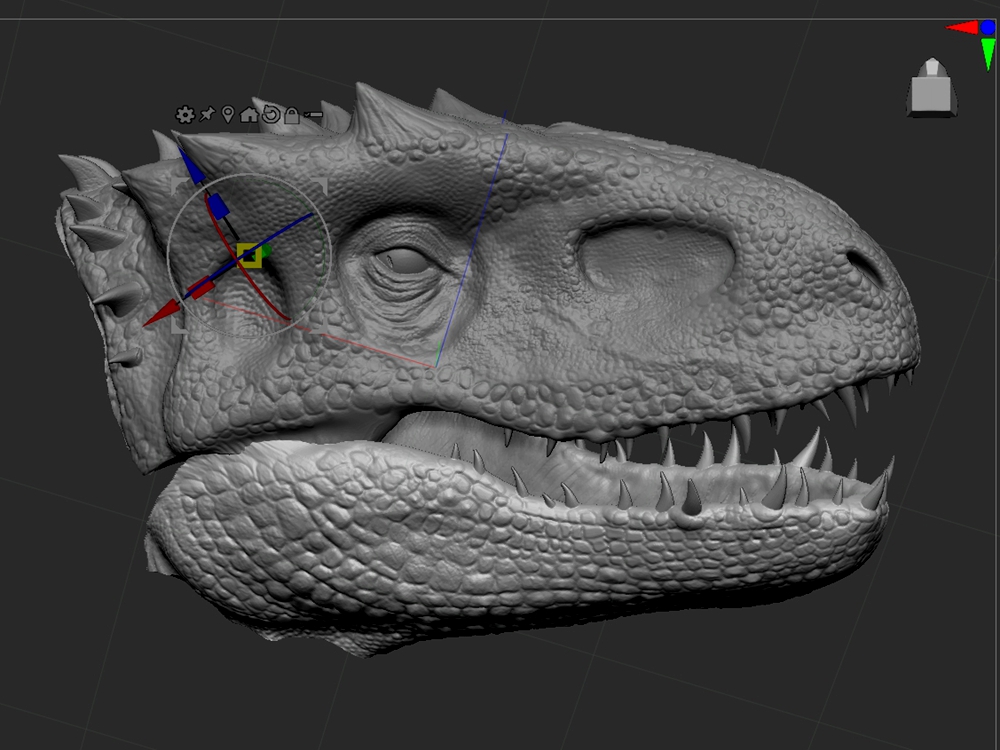

Lots of factories make animatronic dinosaurs these days, but clients often wonder: "Can I judge quality just by looks?" The answer's no, but appearance is still a big deal. Let me break down what actually makes a top-notch animatronic dino, straight from a manufacturer's perspective. Key Elements of High-Quality Animatronic Dinosaurs1. 3D Modeling First - What You See Is What You GetHalf the disappointment comes from the final product not matching what clients pictured. To fix that, we recommend 3D modeling with tools like Zbrush, 3Dmax, or Maya before starting production. We'll send rendered images for approval - yeah, it adds to the timeline, but it's the best way to nail expectations.

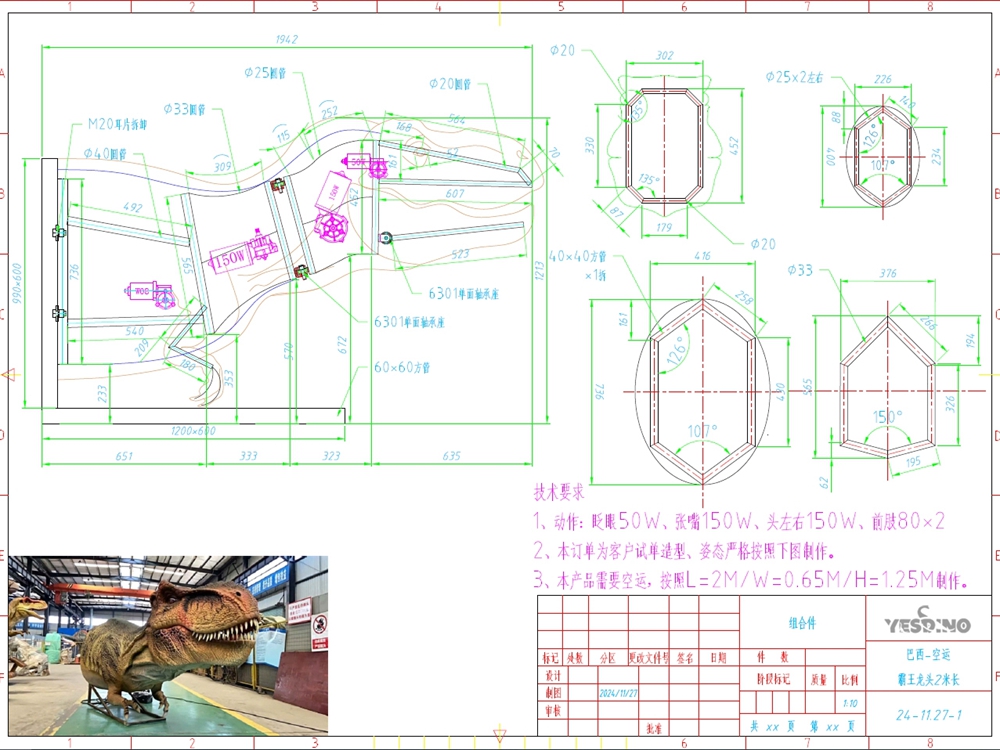

2. Strict CAD Blueprints for the SkeletonThe steel frame inside determines the dino's shape, so CAD mechanical drawings are key. Some factories skip this and wing it based on the builder's experience, but that means inconsistent quality batch to batch. We stick to the drawings - no exceptions.

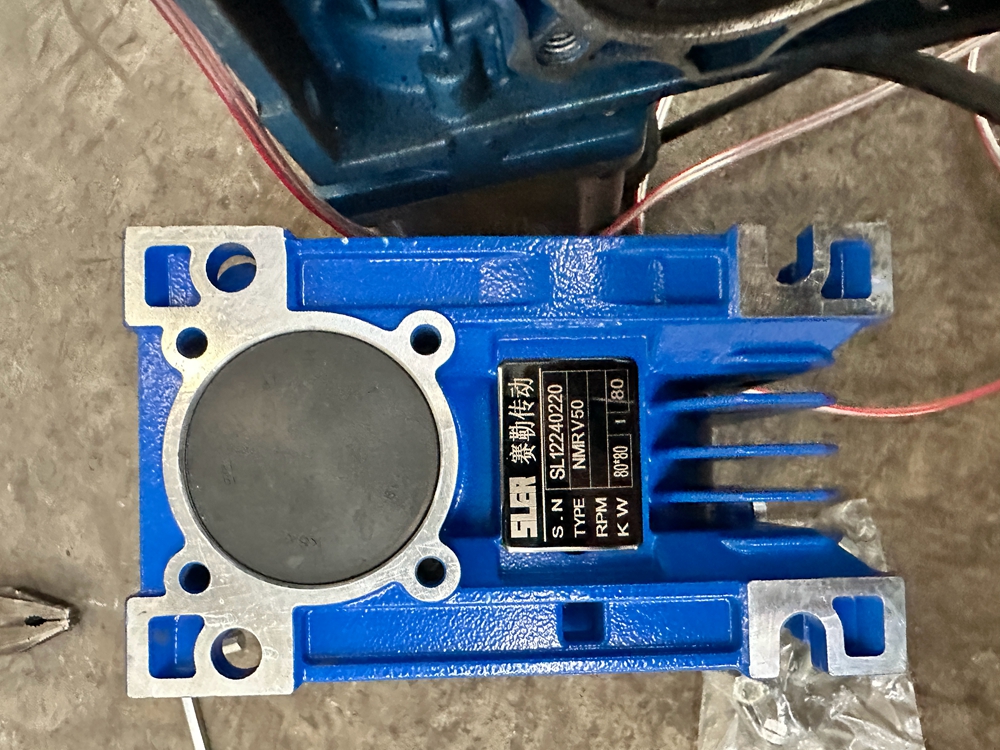

3. Hidden Parts Matter TooMotor, gearbox, bearings, wiring - these are invisible but crucial. Premium motors and gearboxes run cooler and last longer. We use top-tier bearings like SKF, NSK, FAG to avoid noise and wear. For wiring: 0.5mm² for low-current parts (sensors), 2.5mm² copper wire for high-current stuff - all to meet international standards.

4. Silicone Skin Thickness = LifespanFrom experience: 2-3mm skin lasts 3-5 years outdoors. 4-5mm skin? Doubles the lifespan. We're talking about fading, cracking, or tearing from sun and rain - the dino's still there, but it looks rough and ruins the experience. 5. Waterproof & Heat-Dissipating ControllersWhy don't we use surface-mount components on PCBs? They're compact, but tiny pins short out easily in moisture. We prefer through-hole components: better heat dissipation, and wider pins mean water splashes won't cause instant shorts. For extra protection, we can coat the PCB in waterproof gel - it'll work even if submerged. 6. Rust Protection for Exposed Steel BasesStandard steel bases are cheap and easy to weld, but rust fast. Our solution: prime coat, rust-proof top coat, then clear varnish. Lasts years! For dinos in water, go with 304 stainless steel tubing - no rust worries.

If you get a chance to tour a factory before buying, use these points to judge quality. To be honest, most manufacturers in our industry are pretty trustworthy - we're optimistic about the state of things here! |